- Mold material:P20, H13, 718, S136, NAK80, etc

- Part material:PC/ABS, ABS, PC, PA, PMMA, POM, PS

- Mold life: 50,000-1 MILLION

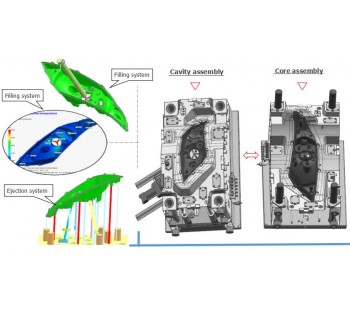

- Product description: Automotive Charger mould, Electronics mould makers in china,with advanced equipment and technology,Chinese local moulding Advantages for your

| Place of Origin: |

Shenzhen (Mainland)

|

Brand Name: |

CMS

|

| Shaping Mode: |

Plastic Injection Mould

|

Product Material: |

Steel

|

| Certificate: |

ISO 9001: 2008 Certificated

|

Brand: |

CMS

|

| Mold type: |

Plastic injection mold

|

Mold base: |

LKM,HASCO,DME etc

|

| Mold Cavity: |

Single or Multi Cavity

|

Mold life: |

50,000-1 MILLION

|

| Part material: |

PC, ABS, PC, PA, PMMA. etc.

|

Model Number: |

C11789

|

| Mold material: |

P20 H13,718,S136,NAK80, etc

|

Product: |

Automobile mold

|

| Standard Part: |

HASCO, DME, MISUMI, Punch

|

Model: |

C11789

|

- 1. Received inquiry

- 2. Quote within 24 hours

- 3. Negotiation

- 4. Place an order

- 5. Drawing

- 6. Mould

- 7. Sample 1st Trial

- 8. Confirm the final Sample

Packaging & Deliver

Packaging Detail:

plastic mould: Good Quality Carton Packing,Suitable for the export

Delivery Detail: In 15--20 days upon receipt of the deposit

Why Choose Us?

1. We have been engaged in mould field for more than 20 years and have much experience in manufacturing Plastic Injection Mould, precision parts mould etc.

2. We are market-leader in this line in mould aspects in China.

3. Reasonable collocation to moulds to save cost

4. mould design is decided by customer’s requests.such an cycle time.employee quantity.mould machine specification.shrinkage of certain plastic material ect.

5. mould making processes can be tracking according to schedule

6. We are always searching technical commucation with our customers.The purpose is to prevent misunderstanding and modification after fineshing moulds.

7. We can supply you the schedule report.inspection report’.warranty of every mould and the video for the mould

8. We will reply your inquiry within 24 hours.

By {$ member [validator]} certification

By {$ member [validator]} certification