Design and development

Case of normal molding

|—High gloss mold

|—Difficult process by CNC machine

|—Perfect polishing of the cavity and core

|—Extremely sort cycle time

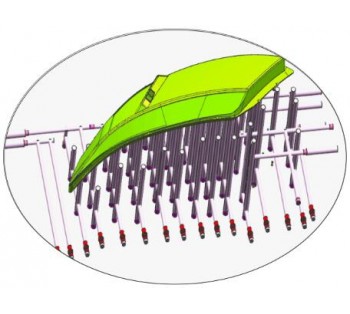

|—Difficult ejection by vacuum air of core

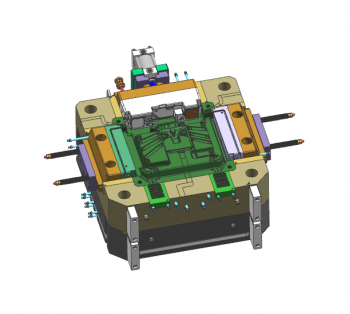

Customer : Volkswagen

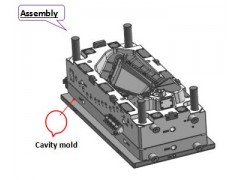

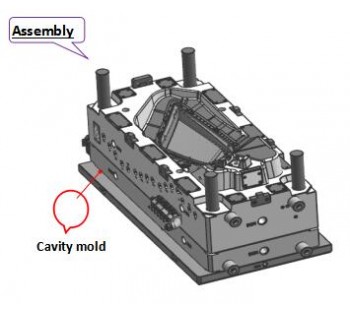

Part size: 532.9X210.8X387.7MM

Part material: PC

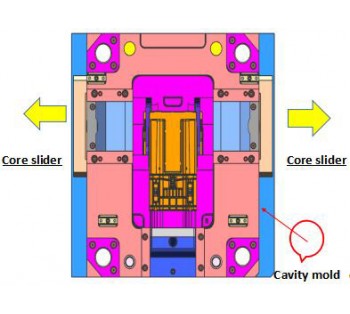

Cavity Number: 1x1

Cycle time: 75S

Design time: 5 work days

Manufacture time: 40 work days

Manufacture date: 2013.10

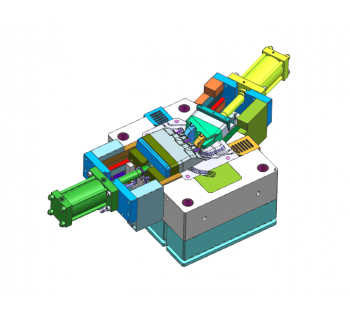

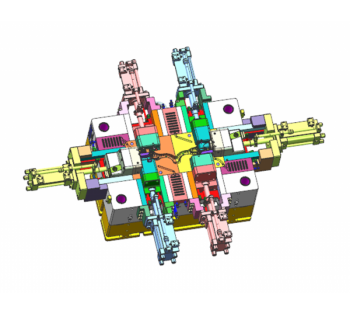

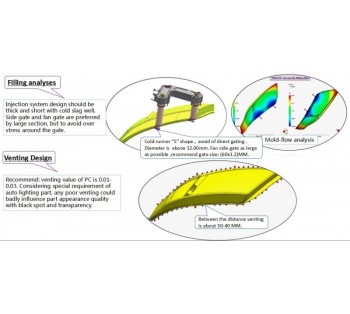

Design points

Manufacture requirements

Material

Manufacture requirements

Polishing process

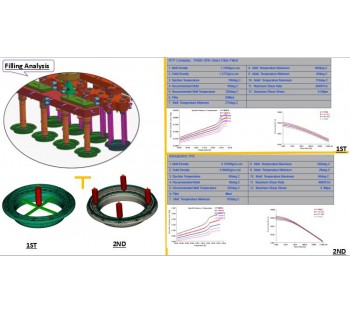

Try Out

Part material-PC property

Physical property : No fixed shape, odorless, Inodorous, non-toxic and transparent thermoplastics Polymer.

Specific density: 1.18-1.20.

Glass transition temperature: 140-150.

Melting point: 220-230. With certain chemical resistance and oil resistance. Medium viscosity PC is with high transparency and 180-210℃ heat resistance.

Mechanical property:Good impact resistance, steady dimension. It could keep high mechanical strength in a broad temperature range. Its disadvantage is poor endurance and wearing resistance.

Thermal property: decomposition temperature is above 300℃. Long term work temperature is up to 120℃, with good cold resistance, brittle temperature is as low as 100℃ below. Long term work temperature ranges from -60℃ to 120℃.

Electrical property: low molecular polarity and good dielectric property.Aging resistance and heat resistance property: pretty good aging resistance property. Inflammable, flame is light yellow with black smoke. Oxygen index is only 25%, self-extinguishing away from fire. Normally modified halide, antimonies hydride, magnesium hydroxide, Phosphine acid, red phosphorus are added to raise flammability.

Optical property: Non-crystalline material, pure PC is colorless and transparent with good light transmission.

Application:

1.High transparency and high impact resistance field, such as CD.

2.Auto industry, for headlight, sidelight, tail lamp, mirror, glass, interior and exterior decoration parts and instrument.

3.Electronics, low voltage cubicle connector, insulating plugs, insulating bush, machine tool protection switch, hollow brick housing,instrument box and office automation equipment.

Cost: POF PC material price is about RBM25-35/kg.

Mold temperature and even cooling will directly .

Proportion of cooling diameter, waterline to part distance, cooling space should be strictly under control of 1:2:5:4. Normal cooling diameter is 12mm, waterline to part distance is 30mm, and cooling space is 50mm.

Avoid pool type cooling as much as possible.

Double angled cooling shall be used to keep even cooling in cavity &core when necessary.

Mold temperature with PC material is 100-120℃. Avoid use of rubber seal ring, heat-resistant flu rubber seal could be appropriately used when necessary. Its working temperature: -30~+250 ℃

Engraving of Lens is different from other mould. The engraving of normal part is reversed in cavity& core, viewing from engravings direction. While core engraving of lens mould is positive direction, cavity engraving is reversed because lens is normally viewed from part visible surface.

PF MOLD CO.,LTD

By {$ member [validator]} certification

By {$ member [validator]} certification